About us

PAMA PAPER MACHINERY is a specialized provider of equipment for the folding carton and corrugated packaging industries in East-Central Europe.

Our products have earned a strong reputation for competitive pricing and superior quality within the printing and packaging sectors. In collaboration with our partners and manufacturers, we are deeply committed to delivering optimized product solutions and technological innovations that meet the evolving needs of our valued customers.

- 300+ Installed Machines: Proven expertise and customer satisfaction

- 30+ YEARS OF EXPERIENCE: Reliable, innovative solutions

- 6 Service Centers: Fast, local support across Eastern and Central Europe

- Multiple Training Centers available: Essential skills and hands-on experience

- High Quality, Competitive Pricing: Exceptional value without compromise

Machines

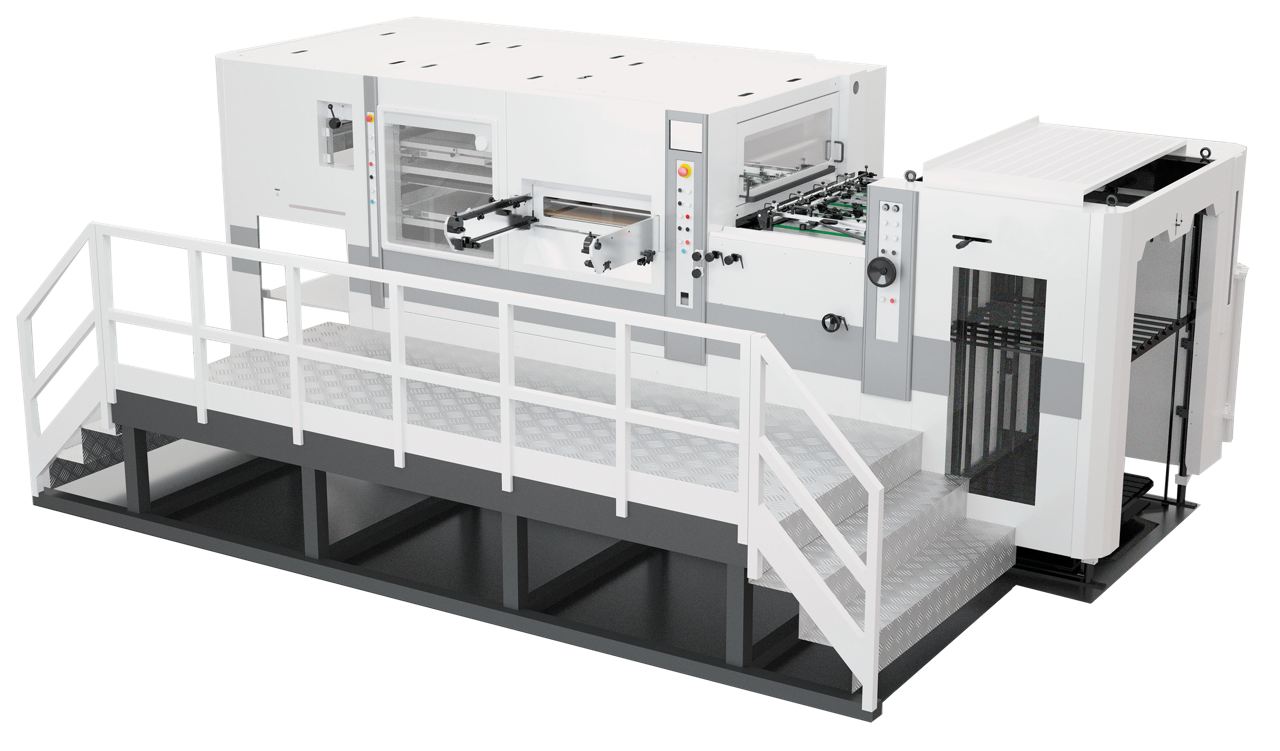

DIE CUTTER

ALPES HD – AUTOMATIC CORRUGATE

| SPECIFICATIONS | 1500 | 1700 | 1800 | 1900 | 2100 | 2500 |

|---|---|---|---|---|---|---|

| Maximum Sheet Size (mm) | 1520 × 1100 mm | 1720 × 1200 mm | 1820 × 1300 mm | 1920 × 1300 mm | 2120 × 1500 mm | 2520 × 1700 mm |

| Minimum Sheet Size (mm) | 750 × 550 mm | 850 × 600 mm | 900 × 650 mm | 950 × 650 mm | 1050 × 750 mm | 1250 × 850 mm |

| Maximum Diecutting Size | 1500 × 1080 mm | 1700 × 1080 mm | 1800 × 1280 mm | 1900 × 1280 mm | 2100 × 1480 mm | 2500 × 1680 mm |

| Maximum Mechanical Speed | 6000 Sheets/h | 5000 Sheets/h | 4200 Sheets/h | 4200 Sheets/h | 3600 Sheets/h | 2600 Sheets/h |

| Sheet Thickness | ||||||

| a. Corrugated | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm |

| b. Plastic and Display | Within 3 mm | Within 3 mm | Within 3 mm | Within 3 mm | Within 3 mm | Within 3 mm |

| Diecutting Precision | 0.3 mm | 0.3 mm | 0.3 mm | 0.3 mm | 0.3 mm | 0.3 mm |

| Total Power (kW) | 33 kW | 37 kW | 41 kW | 41 kW | 55 kW | 65 kW |

| Max. Diecutting Pressure | 350 Tons | 400 Tons | 450 Tons | 450 Tons | 450 Tons | 550 Tons |

| Inner Chase Size |

1550 × 1124 mm |

1750 × 1224 mm | 1900 × 1324 mm | 1950 × 1324 mm | 2150 x 1524 mm | 2550 × 1724 mm |

| ALSO AVAILABLE: | Preloader (Semi-auto/Auto), Chase Preparation unit, Elevation - 300mm High, Pallet Inserter, Heating device plate | |||||

| REMARK: | All automatic machines are equiped with Stripping unit and Gripper Margin removable unit | |||||

ALPES HD – SEMI AUTOMATIC CORRUGATE

| SPECIFICATIONS | 1500 | 1700 | 1800 | 1900 | 2100 | 2500 |

|---|---|---|---|---|---|---|

| Maximum Sheet Size (mm) | 1520 × 1100 mm | 1720 × 1200 mm | 1820 × 1300 mm | 1920 × 1300 mm | 2120 × 1500 mm | 2520 × 1700 mm |

| Minimum Sheet Size (mm) | 750 × 550 mm | 850 × 600 mm | 900 × 650 mm | 950 × 650 mm | 1050 × 750 mm | 1250 × 850 mm |

| Maximum Diecutting Size | 1500 × 1080 mm | 1700 × 1080 mm | 1800 × 1280 mm | 1900 × 1280 mm | 2100 × 1480 mm | 2500 × 1680 mm |

| Maximum Mechanical Speed | 4000 Sheets/h | 3800 Sheets/h | 3600 Sheets/h | 3600 Sheets/h | 3000 Sheets/h | 2600 Sheets/h |

| Sheet Thickness | ||||||

| a. Corrugated | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm | 1.5-12 mm |

| b. Plastic and Display | Within 3 mm | Within 3 mm | Within 3 mm | Within 3 mm | Within 3 mm | Within 3 mm |

| Minimum Gripper Waste | 10 mm | 10 mm | 10 mm | 10 mm | 10 mm | 10 mm |

| Diecutting Precision | 0.3 mm | 0.3 mm | 0.3 mm | 0.3 mm | 0.3 mm | 0.3 mm |

| Total Power (M/S/DS model) | 22, 23, 24 kW | 26, 27, 28 kW | 26, 27, 28 kW | 27, 28, 29 kW | 28, 29, 30 kW | 32, 35, 38 kW 5 kW |

| Max. Diecutting Pressure | 350 Tons | 400 Tons | 450 Tons | 450 Tons | 450 Tons | 550 Tons |

| Inner Chase Size |

1550 × 1124 mm |

1750 × 1224 mm | 1900 × 1324 mm | 1950 × 1324 mm | 2150 x 1524 mm | 2550 × 1724 mm |

| ALSO AVAILABLE: | Retractable Fedder, Batch Delivery, Elevation - 300mm High, Pallet Inserter, Heating Device Plate | |||||

| REMARK: | Available models: M: Non-stipping; S: Stipping; DS: Stipping and Gripper Margin Removable Unit | |||||

ALPES HD – AUTOMATIC CARTON

| SPECIFICATIONS | 820 - SE | 1060 SV/SVB (*with Blanking unit) | 1150 - SE | 1300 - SC | AVAILABLE OPTIONS: |

|---|---|---|---|---|---|

| Maximum Sheet Size (mm) | 820 x 570 mm | 1060 × 750 mm | 1150 × 830 mm | 1300 × 950 mm | ARC Cut to mark register |

| Minimum Sheet Size (mm) | 280 × 230 mm | 400 × 330 mm | 550 × 450 mm | 550 × 450 mm | Automatic non-stop feeder |

| Maximum Cutting Size | 810 × 565 mm | 1050 × 735 mm | 1140 × 820 mm | 1290 × 940 mm | Preset function |

| Minimum Gripper Margin | 8 mm (Gripper margin 3 mm) | 8 mm (Gripper margin 3 mm) | 8 mm (Gripper margin 3 mm) | 8 mm (Gripper margin 3 mm) | Ultrasonic double sheet detection |

| Die Cutting Knife Height | 23.8 mm | 23.8 mm | 23,8 mm | 23,8 mm | Paper pusher on feeder (side and back) |

| Chase Interior Size | 830 × 590 mm | 1070 × 760 mm | 1160 × 848 mm | 1310 × 970 mm | Air suction system, Air blow at punching unit |

| Cutting Plate Size | 844 × 568 mm | 1084 × 750 mm | 1196 × 828 mm | 1325 × 945 mm | Laser sensor at front lays |

| Sheet Thickness | Cardboard 0,1 - 1, 5 mm | Cardboard 0,1 - 1, 5 mm | Cardboard 0,1 - 1. 5 mm | Cardboard 0,1 – 2 mm | 300 mm machine elevation |

| Corrugated board E, B flute | Corrugated board E, B flute | Corrugated board up to B flute | Corrugated board up to B flute | Inspection camera on feeder board | |

| Maximum Cutting Pressure | 180 Tons | 300 Tons | 300 Tons | 350 Tons | Anti-static device |

| Maximum Speed | 8000 Sheets/h | 9000 Sheets/h | 7000 Sheets/h | 7200 Sheets/h | Automatic pressure control |

| Total Power |

12,1 kW |

23,6 kW / 27 kW (*with Blanking unit) | 30 kW | 37 kW | FEATURES: |

| Machine Weight | 11 Tons | 16,5 Tons / 19,6 Tons (*with Blanking unit) | 30 Tons | 28 Tons | Gripper bar position lay on diecutting |

| Machine Size (L × W × H) | 4624 × 2352 × 1725 mm | 5643 × 2185 × 2219 mm | 6334 × 4390 × 2465 mm | 7319 × 2610 × 2470 mm | Stripping and blanking unit |

| (with stripping) | 6595 × 4827 × 2666 mm (*with Blanking unit) | Stripping unit microadjustment Feeding table positioning |

REMARK: This machine is not yet available in all countries. Approvals for additional markets are currently in progress.

ALPES PRO – AUTOMATIC CARTON

| SPECIFICATIONS | 60 | 76 | 85 | 106 |

|---|---|---|---|---|

| Maximum Sheet Size (mm) | 600 x 440 mm | 760 x 600 mm | 850 x 600 mm | 1060 x 750 mm |

| Minimum Sheet Size (mm) | 210 x 180 mm | 310 x 310 mm | 310 x 310 mm | 380 x 380 mm |

| Maximum Diecutting Size | 580 x 410 mm | 750 x 580 mm | 840 x 580 mm | 1040 x 720 mm |

| Inside Chase | 850 x 610 mm | 940 x 610 mm | 1120 x 760 mm | |

| Minimum Gripper Margin | 8 mm | 8 mm | 8 mm | 9 mm |

| Sheet Thickness | 100 ~ 1200 g/m2 | 80 g/m2 up to E flute | 80 g/m2 up to E flute | 120 g/m2 up to E flute |

| Corrugated | Corrugated | Corrugated | ||

| Maximum Diecutting Speed | 6500 Sheets/h | 7000 Sheets/h | 7000 Sheets/h | 7500 Sheets/h |

| Maximum Working Pressure | 150 Tons | 200 Tons | 200 Tons | 300 Tons |

| Total Power | 15 kW | 14 kW | 14 kW | 22 kW |

| Dimension (incl. platform) | L3000 x W1600 x H2000 mm | L4900 x W1900 x H2000 mm | L4900 x W2000 x H2000 mm | L6000 x W4150 x H2300 mm |

| Machine Weight | 5,5 Tons | 13,5 Tons | 14,5 Tons | 18 Tons |

| OPTIONS: | Blanking unit, Heating plate, Pre-loader , Anti-static /Air blower device for thin paper, Chase changer, Make ready table for stripping, Quick lock bar. | |||

| REMARK: | Foil Stamping machines (Longitudinal and Transversal directions with or without Stripping section) also available. | |||

ALPES PRO – AUTOMATIC CORRUGATE

| SPECIFICATIONS | 1650 - TOP FEEDER | 1650 - LEAD EDGE FEEDER | 1650 - BOTTOM SUCTION FEEDER |

|---|---|---|---|

| Maximum Sheet Size (mm) | 1650 × 1200 mm | 1650 × 1200 mm | 1650 × 1200 mm |

| Minimum Sheet Size (mm) | 680 × 520 mm | 680 × 520 mm | 680 × 520 mm |

| Maximum Diecutting Size | 1630 × 1180 mm | 1630 × 1180 mm | 1630 × 1180 mm |

| Inside Chase | 1660 × 1215 mm | 1660 × 1215 mm | 1660 × 1215 mm |

| Minimum Gripper Margin | 12 mm | 12 mm | 12 mm |

| Maximum Pressure | 400 Tons | 400 Tons | 400 Tons |

| Paper Thickness | Cardboard- Minimum ≥350g/m² | Corrugated {paper} 2-9mm | Corrugated {paper} 2-9mm |

| Corrugated 1-7 mm | |||

| Maximum Diecutting Speed | 5000 Sheets/h | 5000 Sheets/h | 5000 Sheets/h |

| Total Power | 40 kW | 45 kW | 45 kW |

| Dimensions (L × W × H) (incl. platform) | 10570 × 6000 × 2810 mm (incl. Pre-loader) | 10500 × 6150 × 2500 mm (incl. Pre-loader) | 11600 × 6000 × 2500 mm |

| Weight | 32 Tons | 33 Tons | 33 Tons |

| OPTIONS: | Preloader, Breaker (1 or 2 Stations) + Turning table, Gripper Margin Removal + 300mm Elevation machine | ||

ALPES ST – SEMI AUTOMATIC CORRUGATE

| SPECIFICATIONS | 1100 | 1300 | 1500 | 1600 |

|---|---|---|---|---|

| Maximum Sheet Size (mm) | 1110 × 790 mm | 1290 × 940 mm | 1500 × 1100 mm | 1650 x 1200 mm |

| Minimum Sheet Size (mm) | 400 × 350 mm | 470 × 450 mm | 470 × 450 mm | 550 x 500 mm |

| Maximum Die-Cutting Size | 1070 × 770 mm | 1280 × 920 mm | 1480 × 1080 mm | 1620 x 1180 mm |

| Maximum Working Speed | 7500 Sheets/h | 5500 Sheets/h | 5500 Sheets/h | 4500 Sheets/h |

| Main Motor Power | 11 kW | 11 kW | 15 kW | 18,5 kW |

| Maximum Working Pressure | 300 Tons | 300 Tons | 300 Tons | 300 Tons |

| Machine Weight | 16T/17T | 18T/19T | 20T/21T | 22T/23T |

| Dimensions (L × W × H) | 7470 x 4256 x 2350 mm | 9551 x 4506 x 2467 mm | 9956 x 4706 x 2452 mm | 10690 x 5117 x 2582 mm |

| Material | E, B, C, A and AB flute | E, B, C, A and AB flute | E, B, C, A and AB flute | E, B, C, A and AB flute |

| Corrugated paper | Corrugated paper | Corrugated paper | Corrugated paper | |

| (1-7,5 mm Thickness) | (1-8,5 mm Thickness) | (1-8,5 mm Thickness) | (1-8,5 mm Thickness) | |

| White Board 250 g | Card Board 250 g | Card Board 350 g | Card Board 350 g |

FLEXO PRINTER

GIANT HD - VACUUM TYPE

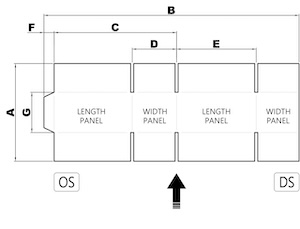

| BOTTOM PRINT | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bottom print w/ double slotter | Bottom print w/ double slotter | Bottom print w/ double slotter | Bottom print w/ double slotter | Bottom print w/ double slotter | |||||||||||||||

| 1600 mm x 2800 mm | 1600 mm x 3400 mm | 1600 mm x 5000 mm | 2000 mm x 5000 mm | 2300 mm x 5500 mm | |||||||||||||||

| MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) |

| 500 | 1650 | 500 | 1650 | 500 | 1650 | 600 | 2100 | 700 | 2300 | ||||||||||

| 1900 | 1900 | 1900 | 2400 | 2800 | |||||||||||||||

| 1075 | (675) | 2875 | 1075 | (675) | 3475 | 1075 | (675) | 5075 | 1340 | (780) | 5100 | 1340 | (800) | 5600 | |||||

| 500 | (300) | 1400 | 500 | (300) | 1700 | 500 | (300) | 2500 | 620 | (340) | 2500 | 620 | (400) | 2750 | |||||

| 150 or 350 | (150) | 700 | (1250) | 150 or 350 | (150) | 850 | (1550) | 150 or 350 | (150) | 1500 | (2350) | 160 or 460 | (170) | 1500 | (2330) | 220 or 400 | (200) | 1600 | (2550) |

| IF D=150 | (150) | 1000 | (1250) | IF D=150 | (150) | 1300 | (1550) | IF D=150 | (150) | 1300 | (1550) | IF D=160 | (170) | 1300 | (1550) | IF D=220 | (200) | 1300 | (1550) |

| E=350 | E=350 | E=350 | E=460 | E=400 | |||||||||||||||

| IF D=350 | (150) | 1000 | (1250) | IF D=350 | (150) | 1300 | (1550) | IF D=350 | (150) | 1800 | (2350) | IF D=460 | (170) | 1800 | (2330) | IF D=400 | (170) | 2000 | (2550) |

| E=150 | E=150 | E=150 | E=160 | E=220 | |||||||||||||||

| 500 | c(300) | 500 | (300) | 500 | (300) | 620 | (340) | 620 | (400) | ||||||||||

| 75 | 130 | 75 | 130 | 75 | 130 | 100 | 150 | 100 | 150 | ||||||||||

| 1600 x 2750 | 1600 x 3350 | 1600 x 4950 | 2000 x 4950 | 2200 x 5450 | |||||||||||||||

| 1900 x 2875 | 1900 x 3475 | 1900 x 5075 | 2400 x 5100 | 2800 x 5600 | |||||||||||||||

| TOP PRINT | TOP PRINT | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Top Print w/ single slotter | Top Print w/ single slotter | Top Print w/ single slotter | Top Print w/ single slotter | ||||||||||||||||

| SPECIFICATIONS | 900 mm x 1800 mm | 900 mm x 2400 mm | 1200 mm x 2400 mm | 1200 mm x 2800 mm | |||||||||||||||

| MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) | MIN. Inline | (Offline) | MAX. Inline | (Offline) | ||||

| A Min. | Max. Sheet Size | 245 | 900 | 245 | 900 | Top 300 | Bottom 320 | 1250 | Top 300 | Bottom 320 | 1250 | ||||||||

| Skip Feeding | 1050 | 1050 | 1500 | 1050 | |||||||||||||||

| B Min. | Max. Sheet Size | 560 | (520) | 1840 | 700 | (580) | 2440 | 770 | (660) | 2440 | 770 | (660) | 2840 | ||||||

| C Min. | Max. Sheet Size | 260 | (240) | 900 | 265 | (270) | 1200 | 365 | (310) | 1200 | 365 | (310) | 1400 | ||||||

| D Min. | Max. Sheet Size | 120 or 140 | (120) | 500 | (780) | 135 or 230 | (135) | 650 | (1065) | 155 or 210 | (155) | 650 | (1045) | 155 or 210 | (155) | 750 | (1245) | ||

| E Min. | Max. Sheet Size | IF D=120 | (120) | 700 | (780) | IF D=135 | (135) | 800 | (1065) | IF D=155 | (155) | 800 | (1045) | IF D=155 | (155) | 1000 | (1245) | ||

| E=140 | E=230 | E=210 | E=210 | ||||||||||||||||

| E Min. | Max. Sheet Size | IF D=140 | (120) | 700 | (780) | IF D=230 | (135) | 800 | (1065) | IF D=210 | (155) | 800 | (1045) | IF D=210 | (155) | 1000 | (1245) | ||

| E=120 | E=135 | E=155 | E=155 | ||||||||||||||||

| D+E {Minimum Sheet Size} | 260 | (240) | 365 | (270) | 365 | (310) | 365 | (310) | |||||||||||

| F Max. | G Min. Sheet Size | 40 | 90 | 40 | 90 | 40 | 90 | 40 | 90 | ||||||||||

| Printing Area | 850 x 1750 | 850 x 2350 | 1180 x 2350 | 1180 x 2750 | |||||||||||||||

| Maximum Unfold Sheet | 900 x 1350 | 900 x 1650 | 1250 x 1650 | 1250 x 1650 | |||||||||||||||

| REMARK: | INLINE machine/Case Maker, OFFLINE machine/Flexo Printer Slotter | ||||||||||||||||||

GIANT PRO – VACUUM TYPE

| SPECIFICATIONS | 618 | 920 | 924 | 1224 | 1228 | 1428 | 1628 | 1632 | 1636 |

|---|---|---|---|---|---|---|---|---|---|

| Maximum Feeding Size (mm) | 600 × 1800 | 900 × 2000 | 900 × 2400 | 1200 × 2400 | 1200 × 2800 | 1400 × 2800 | 1600 × 2800 | 1600 × 3200 | 1600 × 3600 |

| Minimum Feeding Size (mm) | 230 × 435 | 270 × 600 | 270 × 600 | 350 ×600 | 350 × 600 | 365 × 600 | 450 × 600 | 450 × 600 | 450 × 600 |

| Skip Feeding Size (mm) | 800 × 1800 | 1200 × 2000 | 1200 × 2400 | 1500 × 2400 | 1500 × 2800 | 1700 × 2800 | 1900 × 2800 | 1900 × 3200 | 1900 × 3600 |

| Maximum Printing Size (mm) | 600 × 1760 | 900 × 1960 | 900 × 2360 | 1200 × 2360 | 1200 × 2760 | 1400 × 2760 | 1600 × 2760 | 1600 × 3160 | 1600 × 3560 |

| Minimum Slotting Size (Normal knife) | 110 × 110 | 130 × 130 | 130 × 130 | 130 × 130 | 130 × 130 | 130 × 130 | 130 × 130 | 260 × 65 | 260 × 65 |

| Minimum Slotting Size (Reverse knife) | 180 × 55 | 240 × 65 | 240 × 65 | 260 × 65 | 260 × 65 | 260 × 65 | 260 × 65 | 130 × 130 | 130 × 130 |

| Maximum Slotting Depth (mm) | 200 | 250 | 250 | 300 | 300 | 350 | 400 | 400 | 400 |

| Maximum Machine Speed (pcs/min) | 350 | 300 | 300 | 250 | 230 | 220 | 180 | 180 | 160 |

| REMARK: | Skip feed size is not available in Inline configuration. | ||||||||

GIANT PRO – ROLLER TYPE

| SPECIFICATIONS | 1228 | 1426 | 1628 | 1632 | 1636 | 2236 | 2242 | 2636 | 2642 |

|---|---|---|---|---|---|---|---|---|---|

| Maximum Feeding Size (mm) | 1200 × 2800 | 1400 × 2600 | 1600 × 2800 | 1600 × 3200 | 1600 × 3600 | 2200 × 3600 | 2200 × 4200 | 2600 × 3600 | 2600 × 4200 |

| Minimum Feeding Size (mm) | 350 × 600 | 420 × 600 | 450 × 600 | 450 × 600 | 450 × 600 | 500 × 700 | 500 × 700 | 500 × 700 | 500 × 700 |

| Skip Feeding Size (mm) | 1500×2800 | 1700×2600 | 1900 × 2800 | 1900 × 3200 | 1900 × 3600 | 2500 × 3600 | 2500 × 4200 | 2800 × 3600 | 2800 × 4200 |

| Maximum Printing Size (mm) | 1200 × 2760 | 1400 × 2560 | 1600 × 2760 | 1600 × 3160 | 1600 × 3560 | 2200 × 3560 | 2200 × 4160 | 2500 × 3560 | 2500 × 4160 |

| Minimum Slotting Size (Normal knife) | 130 × 130 | 130 × 130 | 130 × 130 | 130 × 130 | 130 × 130 | 150 × 150 | 150 × 150 | 150 × 150 | 150 × 150 |

| Minimum Slotting Size (Reverse knife) | 260 × 65 | 260 × 65 | 260 × 65 | 260 × 65 | 260 × 65 | 360 × 95 | 360 × 95 | 360 × 95 | 360 × 95 |

| Maximum Slotting Depth (mm) | 300 | 350 | 400 | 400 | 400 | 700 | 700 | 700 | 700 |

| Maximum Machine Speed (pcs/min) | 230 | 200 | 180 | 180 | 160 | 140 | 130 | 100 | 80 |

| REMARK: | Skip feed size is not available in Inline configuration. Folder Gluer is available only for following models: 1426, 1628, 1632 and 1636. | ||||||||

GIANT ST – ROLLER TYPE

| SPECIFICATIONS | 920 | 924 | 1224 | 1228 |

|---|---|---|---|---|

| Maximum Sheet Size (mm) | 900 × 2100 | 900 × 2500 | 1200 × 2500 | 1200 × 2900 |

| Minimum Sheet Size (mm) | 300 × 600 | 300 × 600 | 350 × 600 | 350 × 600 |

| Maximum Print Area | 900 × 2000 | 900 × 2400 | 1200 × 2400 | 1200 × 2800 |

| Skip Feed Size | 1200 × 2100 | 1200 × 2500 | 1500 × 2500 | 1500 × 2900 |

| Feeding Tolerance | ± 1,0 | |||

| Printing Tolerance | ± 0,5 | |||

| Slotting Tolerance | ± 1,5 | |||

| Die Cutting Tolerance | ± 1 | |||

| Minimum slotting distance (Normal knife) | 130 × 130 | |||

| Minimum slotting distance (Reverse knife) | 270 × 65 | |||

| Maximum slot depth | 250 | 250 | 300 | 300 |

| Maximum Machine Speed (Sheets/h) | 21000 | 21000 | 15000 | 13500 |

| Working Machine Speed (Sheets/h) | 18000 | 18000 | 12000 | 10800 |

| REMARK: | Inline Folder Gluer Also Available and vacuum type of machine also available. | |||

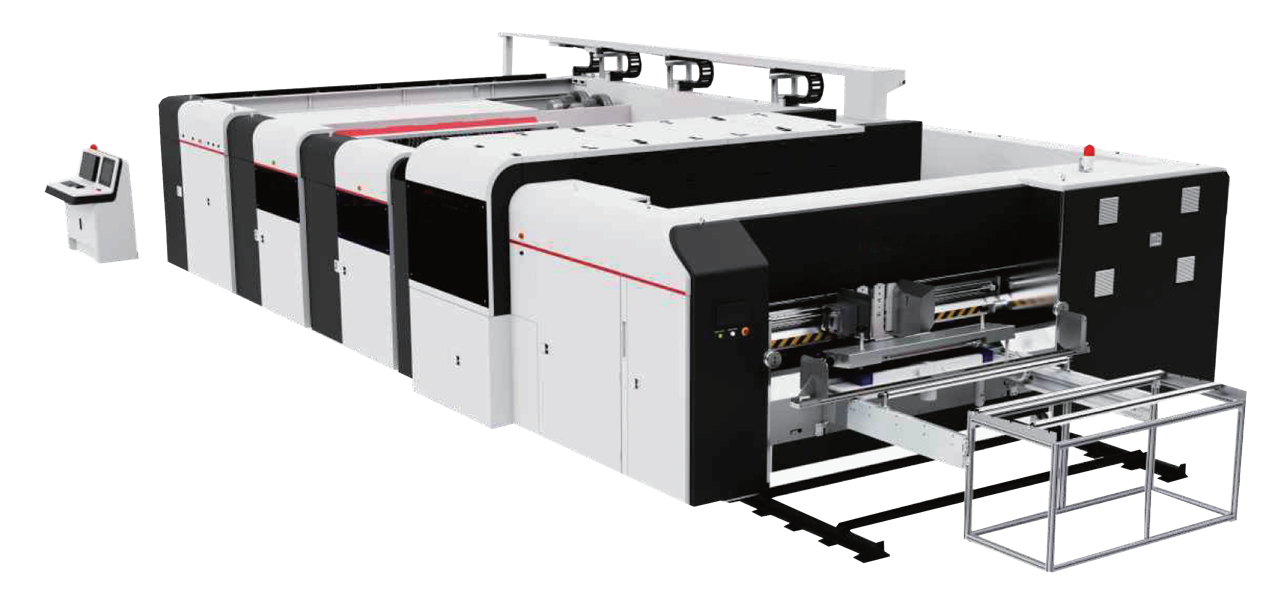

DIGITAL PRINTER HD

| SPECIFICATIONS | Glory 2504 - Single Pass | ||

|---|---|---|---|

| Dimensions | 18000 × 6350 × 3655 mm | ||

| (Printer, primer, drying, varnishing, slotting, and stacking included) | |||

| Installation site requirements | 25280 × 9350 × 4000 mm | Thickness range of media printed | 1-15mm |

| Type of Ink | Aqueous | Applicable media for printing | Corrugated |

| Ink Color | C/M/Y/K | Drying system | Air dry / IR Dry |

| Qty of Print Heads | Maximum 20 Kyocera per color | Printing software | System preset software |

| Maximum Size of Boards (W × L) | 2500 × 3000 mm (+ 2000 mm for slotting) | RIP | Caldera |

| Minimum Size of Boards (W × L) | 600 × 400 mm | Input Format | PDF, JPEG, TIFF, EPS, AI, etc. |

| Maximum Printing Width | 2160 mm | Air source | Flow 0.6m3/min, 0.6mpa |

| Maximum Printing Speed | 180 M/min | Environment Requirement | Relative Humidity: 40% − 60% |

| Resolution | 300×600 / 400×600 / 450×600 / 600×600 (dpi) | Temperature: 22 ̊C − 30 ̊C | |

| REMARK: | Multi Pass machines also available. | ||

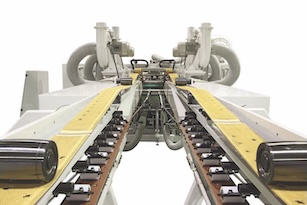

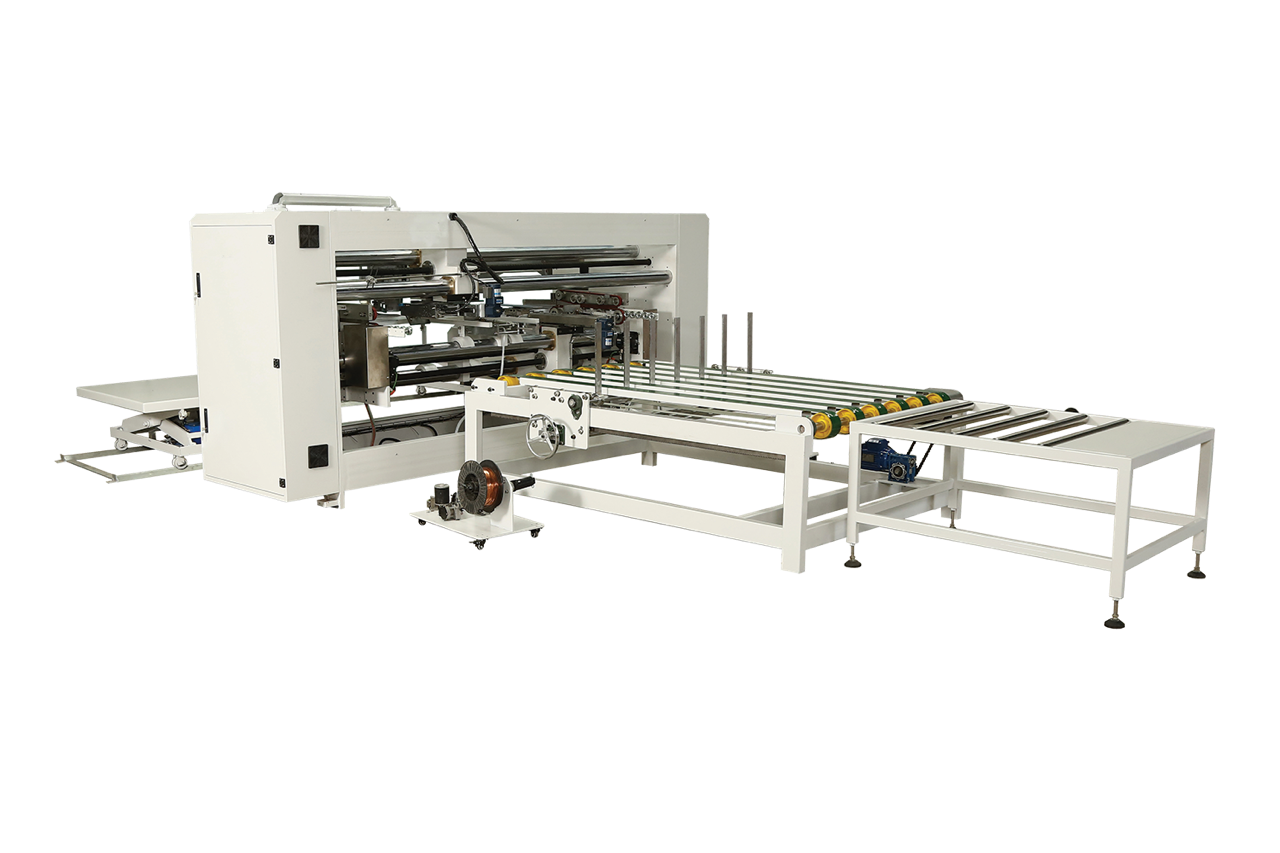

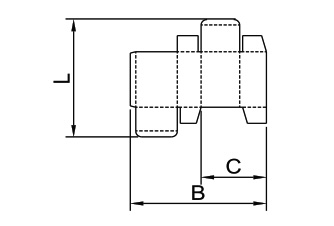

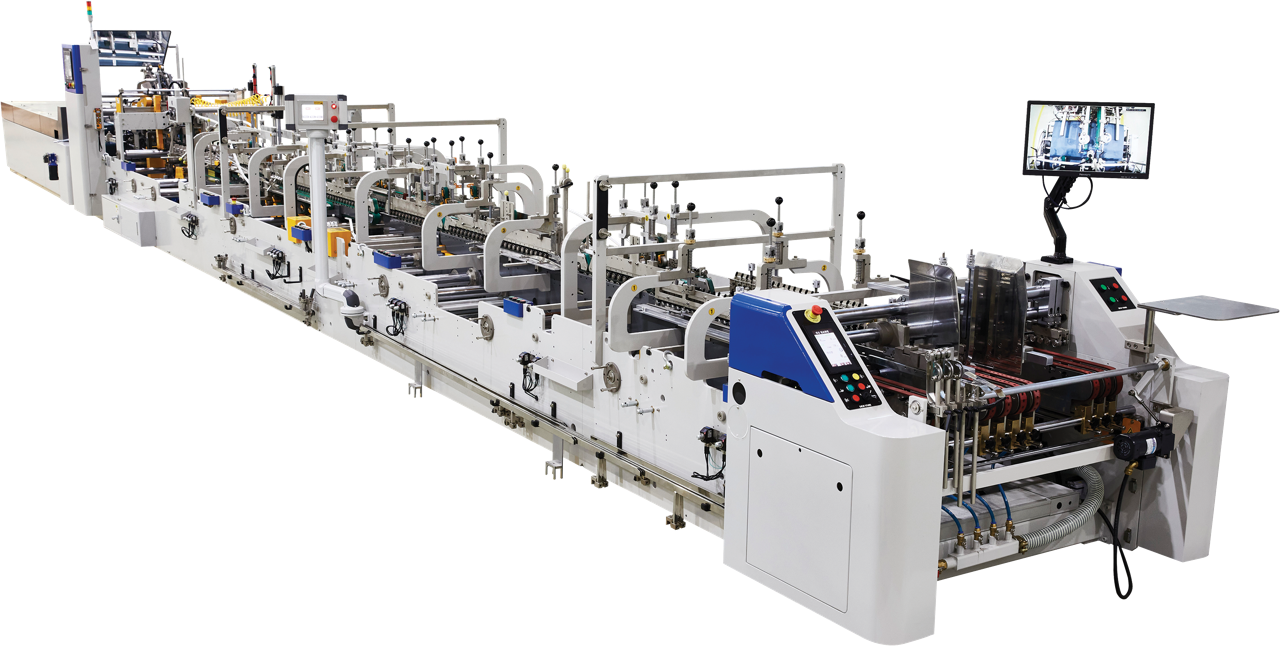

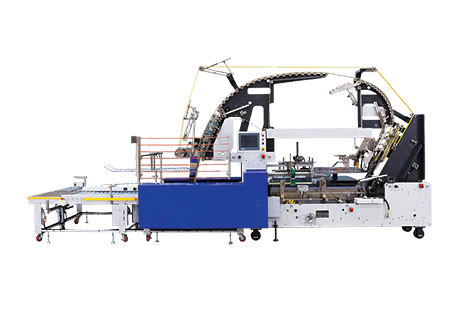

FOLDER GLUER

TITAN HD – CORRUGATE

SOUTH

KOREA

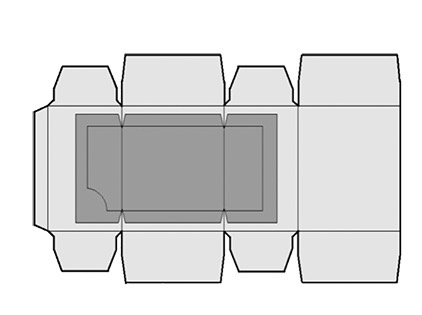

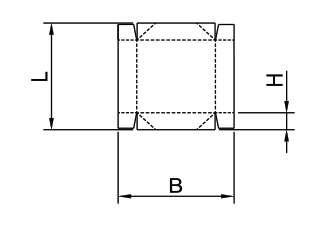

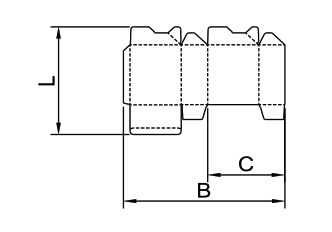

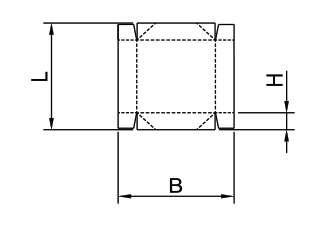

STRAIGHT LINE CARTONS

CRASH-LOCK BOTTOM CARTONS

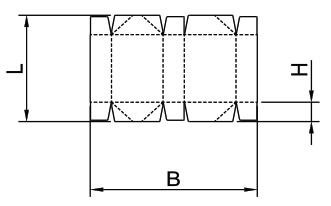

4-CORNER COLLAPSIBLE BOXES

6-CORNER COLLAPSIBLE BOXES

SPANKER

| SPECIFICATIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. STRAIGHT LINE CARTONS | 4. 6-CORNER COLLAPSIBLE BOXES | ||||||||||

| 110 | 135 | 145 | 165 | 110 | 135 | 145 | 165 | ||||

| B (mm) | 140 ~ 1100 | 140 ~ 1350 | 140 ~ 1450 | 140 ~ 1650 | B (mm) | 250 ~ 1000 | 250 ~ 1250 | 250 ~ 1350 | 250 ~ 1550 | ||

| L (mm) | 65 ~ 900 | 65 ~ 1000 | 65 ~ 1000 | 65 ~ 1000 | L (mm) | 185 ~ 800 | 185 ~ 800 | 185 ~ 800 | 185 ~ 800 | ||

| C (mm) | 65 ~ 540 | 65 ~ 660 | 65 ~ 660 | 65 ~ 610 | H (mm) | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | ||

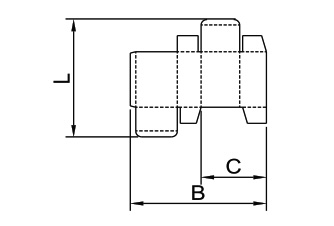

| 2. CRASH-LOCK BOTTOM CARTONS | FOLDING BOX BOARD | ||||||||||

| 110 | 135 | 145 | 165 | 1. Folding Cartons | 200 ~ 800 | 200 ~ 800 | 200 ~ 800 | 200 ~ 800 | |||

| B (mm) | 170 ~ 1075 | 170 ~ 1325 | 170 ~ 1425 | 170 ~ 1625 | 2. Lock Bottom Cartons | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | ||

| L (mm) | 120 ~ 900 | 120 ~ 1000 | 120 ~ 1000 | 120 ~ 1000 | 3. Collapsible Boxes | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | ||

| C (mm) | 80 ~ 530 | 80 ~ 655 | 80 ~ 705 | 80 ~ 798 | CORRUGATED BOARD | ||||||

| 1. Folding Cartons | E, B, A | E, B, A | E, B, A | E, B, A | |||||||

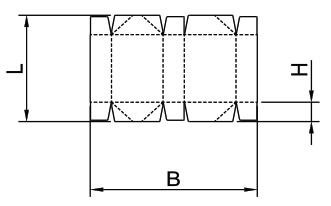

| 3. 4-CORNER COLLAPSIBLE BOXES | 2. Lock Bottom Cartons | E, B | E, B | E, B | E, B | ||||||

| 110 | 135 | 145 | 165 | 3. Collapsible Boxes | E | E | E | E | |||

| B (mm) | 150 ~ 1000 | 150 ~ 1250 | 150 ~ 1350 | 250 ~ 1550 | LENGHT (meters) | 14,9 | 16,2 | 16,2 | 18,2 | ||

| L (mm) | 150 ~ 800 | 150 ~ 800 | 150 ~ 800 | 185 ~ 800 | WEIGHT (tons) | 11,5 | 13 | 14 | 15 | ||

| H (mm) | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | TOTAL CONNECTED LOAD (kva) | 58 | 58 | 58 | 65 | ||

| AVAILABLE OPTIONS: | Auto-Jog, Spanker, 4/6 Back Fold, 3rd Back Fold, Carton Aligner, Glue Detection Device, {Automatic Glue Supply Device, Inspection Machine, Turning Station (Gyro)} Ejector, Fast Fold, Carton Aligner, Auto Jog, Nick Breaker, Spanker, Final Fold MS Carrier up/down. | ||||||||||

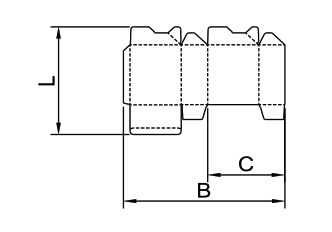

TITAN HD – CARTON

SOUTH

KOREA

STRAIGHT LINE CARTONS

CRASH-LOCK BOTTOM CARTONS

4-CORNER COLLAPSIBLE BOXES

6-CORNER COLLAPSIBLE BOXES

SIG PACK

SIG FEED

| SPECIFICATIONS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. STRAIGHT LINE CARTONS | 4. 6-CORNER COLLAPSIBLE BOXES | ||||||||||

| 70 | 90 | 110 | 135 | 70 | 90 | 110 | 135 | ||||

| B (mm) | 140 ~ 700 | 140 ~ 900 | 140 ~ 1100 | 140 ~ 1350 | B (mm) | 250 ~ 600 | 250 ~ 800 | 250 ~1000 | 250 ~ 1250 | ||

| L (mm) | 65 ~ 900 | 65 ~ 900 | 65 ~ 900 | 65 ~ 1000 | L (mm) | 185 ~ 800 | 185 ~ 800 | 185 ~ 800 | 185 ~ 800 | ||

| C (mm) | 65 ~ 340 | 65 ~ 435 | 65 ~ 540 | 65 ~ 660 | H (mm) | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | ||

| 2. CRASH-LOCK BOTTOM CARTONS | FOLDING BOX BOARD | ||||||||||

| 70 | 90 | 110 | 135 | 1. Folding Cartons | 200 ~ 800 | 200 ~ 800 | 200 ~ 800 | 200 ~ 800 | |||

| B (mm) | 170 ~ 675 | 170 ~ 875 | 170 ~ 1075 | 170 ~ 1325 | 2. Lock Bottom Cartons | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | ||

| L (mm) | 120 ~ 900 | 120 ~ 900 | 120 ~ 900 | 120 ~ 1000 | 3. Collapsible Boxes | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | 250 ~ 800 | ||

| C (mm) | 80 ~ 328 | 80 ~ 435 | 80 ~ 530 | 80 ~ 645 | CORRUGATED BOARD | ||||||

| 1. Folding Cartons | E, B | E, B | E, B | E, B | |||||||

| 3. 4-CORNER COLLAPSIBLE BOXES | 2. Lock Bottom Cartons | E, B | E, B | E, B | E, B | ||||||

| 70 | 90 | 110 | 135 | 3. Collapsible Boxes | E | E | E | E | |||

| B (mm) | 150 ~ 600 | 150 ~ 800 | 150 ~ 1000 | 150 ~ 1250 | LENGHT (meters) | 17,1 | 17,1 | 17,1 | 18,4 | ||

| L (mm) | 150 ~ 800 | 185 ~ 800 | 150 ~ 800 | 150 ~ 800 | WEIGHT (tons) | 10 | 11 | 12 | 13,5 | ||

| H (mm) | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | 30 ~ 150 | TOTAL CONNECTED LOAD (kva) | 67 | 67 | 67 | 78 | ||

| AVAILABLE OPTIONS: | Sig Feed/Sig Pack, Auto-Jog, Spanker, 4/6 Back Fold, 3rd Back Fold, Carton Aligner, Glue Detection Device, Automatic Glue Supply Device, Inspection Machine, Turning Station (Gyro), Ejector, Fast Fold, Carton Aligner, Auto Jog, Nick Breaker, Spanker, Final Fold MS Carrier up/down, Camera Inspection Control | ||||||||||

TITAN PRO – CARTON AND CORRUGATE

| SPECIFICATIONS | 650 | 850 | 1100 | 1450 | 1700 | 2100 | 2300 | 2800 | 3200 | |

|---|---|---|---|---|---|---|---|---|---|---|

| {Maximum Sheet Size} | 650 × 700 | 850 × 900 | 1100 × 900 | 1450 × 1300 | 1700 × 1300 | 2100 × 1300 | 2300 × 1300 | 2800 × 1300 | 3200 × 1300 | |

| {Minimum Sheet Size} | 120 × 70 | 125 × 70 | 130 × 70 | 520 × 180 | 520 × 180 | 520 × 180 | 520 × 180 | 520 × 180 | 520 × 180 | |

| Cardboard | 250 - 800 g | 250 - 800 g | 250 - 800 g | 300 - 800 g | 300 - 800 g | 300 - 800 g | 300 - 800 g | 300 - 800 g | 300 - 800 g | |

| Corrugated paper | F, E | F, E | F, E | F, E, C, B, A, EB, AB | F, E, C, B, A, EB, AB | F, E, C, B, A, EB, AB | F, E, C, B, A, EB, AB | F, E, C, B, A, EB, AB | F, E, C, B, A, EB, AB | |

| Maximum Speed | 500 M/min | 500 M/min | 500 M/min | 200 M/min | 200 M/min | 200 M/min | 200 M/min | 200 M/min | 200 M/min | |

| Lenght | 19600 mm | 19600 mm | 19600 mm | 23000 mm | 23000 mm | 23000 mm | 23000 mm | 23000 mm | 23000 mm | |

| Width | 1350 mm | 1500 mm | 1800 mm | 2240 mm | 2440 mm | 2840 mm | 3040 mm | 3540 mm | 3940 mm | |

| Height | 1450 mm | 1450 mm | 1450 mm | 2000 mm | 2000 mm | 2000 mm | 2000 mm | 2000 mm | 2000 mm | |

| Power | 33,5 kW | 33,5 kW | 33,5 kW | 52 kW | 52 kW | 52 kW | 52 kW | 52 kW | 52 kW | |

| Maximum Air Displacement | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | 0,7 m3/min | |

| Weight | 6,5 Tons | 7 Tons | 8,5 Tons | 15,5 Tons | 16 Tons | 16,5 Tons | 17 Tons | 18 Tons | 20 Tons | |

OPTIONS: Different Inspection systems (Printing Quality, Bar Code, Glue Inspection), Memory System, Motorised Plate Adjustement, 4/6 Corner System

TITAN ST – STRAIGHT LINE CORRUGATE

| SPECIFICATIONS | 1224 | 1228 | 1632 | 1636 | 2540 | 2545 | |

|---|---|---|---|---|---|---|---|

| Maximum Sheet Size (mm) | 2400 x 1200 | 2800 x 1200 | 3200 x 1600 | 3600 x 1600 | 4000 × 2500 | 4500 × 2500 | |

| Minimum Sheet Size (mm) | 900 x 350 (stitch) 900 x 30 (glue) | ||||||

| Material | 3 ply, 5 ply and 7 ply Corrugated paperboard | ||||||

| Max Glue Box Speed | 200 m/min | ||||||

| Max Stitch Box Speed | 110 pcs/min (3 Stitching Wire) | ||||||

| Stitching Wire | No17 stitching wire | ||||||

| Stitching List | Single Stitching, Double Stitching | ||||||

| Stitching Distance | 30 - 100 mm | ||||||

| REMARK: | Stitching unit also available | ||||||

TITAN ST – SEMI AUTO STITCHER AND GLUER

| SEMI AUTO STITCHER | 2800 | SEMI AUTO FOLDER GLUER | 2600 | TWO PIECE JOINT STITCHER | 2400 | 3000 | 3600 | 4000 | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Sheet Width | 2800mm | Speed | 10-80 m/min | Maximum Size (A+B) x 2 | 4800 mm | 6000 mm | 7200 mm | 8000 mm | |||

| Minimum Sheet Width | 606mm | Maximum Feeding Size | 2600 × 1510 mm | Minimum Size (A+B) x 2 | 1100 mm | 1100 mm | 1100 mm | 1100 mm | |||

| Maximum Sheet Length | 1515mm | Minimum Feeding Size | 610 × 300 mm | Maximum Length (A) | 2250 mm | 2850 mm | 3450 mm | 3850 mm | |||

| Minimum Sheet Length | 300mm | Power | 3.5 kw | Minimum Length (A) | 400 mm | 400 mm | 400 mm | 400 mm | |||

| Side Mark | 125-500mm | {Total weight} | 2000 kg | Maximum Width (B) | 2250 mm | 2850 mm | 3450 mm | 3850 mm | |||

| Stitching Flap | 30-50mm | Machine Dimension | 4500 × 2000 × 1800 mm | Minimum Width (B) | 150 mm | 150 mm | 150 mm | 150 mm | |||

| Paperboard Thickness | 3-10 mm | Minimum Height (C+D+C) | 400 mm | 400 mm | 400 mm | 400 mm | |||||

| Machine Speed | 500 stitches/min | Maximum Machine Speed | 500 stitches/min | 500 stitches/min | 500 stitches/min | 500 stitches/min | |||||

| Stitching Distance | 20-120 mm | Stitching Distance | 30-120 mm | 30-120 mm | 30-120 mm | 30-120 mm | |||||

| Number of Stitching | 2-99 stitches | Number of Stitching | 2-99 stitches | 2-99 stitches | 2-99 stitches | 1-99 stitches | |||||

| Stitching Wire | Width: 1.95 (1.8)mm (+/- 0.05mm) | Corrugated Materials | 5ply, 7ply, | 5ply, 7ply, | 5ply, 7ply, | 5ply, 7ply, | |||||

| Thickness: 0.75mm (+/- 0.03mm) | max 14 mm | max 14 mm | max 14 mm | max 14 mm | |||||||

| Stitching Forming | ① // // // ② / / / ③ // / // | Thickness | Thickness | Thickness | Thickness | ||||||

| Height of Feeder | 900 mm | Total Power | 6.5 kW | 6.5 kW | 6.5 kW | 6.5 kW | |||||

| Total Power | 4.5 kW | Voltage | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase | 380V, 50HZ, 3phase | |||||

| Voltage | 380V, 50HZ, 3 phase | Machine Weight | 3,5 Tons | 4,2 Tons | 4,8 Tons | 5 Tons | |||||

| Weight | 2 Tons | Machine Dimension | 6500 × 3600 × 2000 mm | 6500 × 4200 × 2000 mm | 6500 × 4800 × 2000 mm | 6500 × 5200 × 2000 mm | |||||

| Machine Dimension | 2850×2700×1900 mm | ||||||||||

| REMARK: | Stacker also available. | ||||||||||

WINDOW PATCHER HD

| SPECIFICATIONS | 1000 BF / SV | 1000 DBF / DSV | 1400 SV | 1400 DSV | ||||

|---|---|---|---|---|---|---|---|---|

| Blank Length | 100 mm ~ 710 mm | 100 mm ~ 710 mm | Blank Length | 100 mm ~ 1020 mm | 100 mm ~ 1020 mm | |||

| Blank Width | 80 mm ~ 1000 mm | 80 mm ~ 480 mm | Blank Width | 80 mm ~ 1400 mm | 80 mm ~ 680 mm | |||

| Film Length | 38 mm ~ 520 mm | 38 mm ~ 520 mm | Film Length | 55 mm ~ 670 mm | 55 mm ~ 670 mm | |||

| Film Width | 30 mm ~ 840 mm | 30 mm ~ 400 mm | Film Width | 30 mm ~ 1040 mm | 30 mm ~ 500 mm | |||

| Film Thickness | 0.03 mm ~ 0.20 mm (Straight Preparation) | Film Thickness | 0.03 mm ~ 0.20 mm (Straight Preparation) | |||||

| Feed Material | Cardboard 250 ~ 800 gsm | Feed Material | Cardboard 250 ~ 800 gsm | |||||

| ∙ Corrugated board up to B flute 3 mm | ∙ Corrugated board up to B flute 3 mm | |||||||

| Maximum Mechanical Speed | Maximum Mechanical Speed | |||||||

| Length Over Than 330 mm | 9,000 pcs / hour | 18,000pcs / hour | Length Over Than 500 mm | 9,000 pcs / hour | 18,000 pcs / hour | |||

| Length Less Than 330mm | 18,000 pcs / hour | 36,000pcs / hour | Length Less Than 500 mm | 18,000 pcs / hour | 36,000 pcs / hour | |||

| Length Less Than 340 mm | 27,000 pcs / hour | 54,000 pcs / hour | ||||||

| OTHER OPTIONS: | ||||||||

| • Models 600 and 1100 also available | ||||||||

| • Bundle Stacker | ||||||||

LAMINATOR

SERVO LAMINATING MACHINE

| SPECIFICATIONS | 1416AP | 1616AP | 1316 | 1416 | 1616 | 1816 | |||

|---|---|---|---|---|---|---|---|---|---|

| Maximum Sheet Size (mm) | 1450 × 1450 mm | 1650 × 1450 mm | 1300 × 1300 mm | 1450 × 1450 mm | 1650 × 1650 mm | 1850 × 1650 mm | |||

| Minimum Sheet Size (mm) | 450 × 450 mm | 450 × 450 mm | 450 × 450 mm | 450 × 450 mm | 550 × 550 mm | 550 × 550 mm | |||

| Thickness of Litho Sheet (g/m2) | 120 ~ 800 | 120 ~ 800 | 120 ~ 800 | 120 ~ 800 | 150 ~ 800 | 180 ~ 800 | |||

| Thickness of Substrate Sheet | 0,5 ~ 10 | 0,5 ~ 10 | 0,5 ~ 10 | 0,5 ~ 10 | 0,5 ~ 10 | 0,5 ~ 10 | |||

| Machine Speed | 150 m/min | 150 m/min | 150 m/min | 150 m/min | 120 m/min | 100 m/min | |||

| Machine Speed | 10000 Sheets/h | 10000 Sheets/h | 10000 Sheets/h | 9000 Sheets/h | 8000 Sheets/h | 6000 Sheets/h | |||

| Operation Speed | 8000 Sheets/h | 8000 Sheets/h | 8000 Sheets/h | 7200 Sheets/h | 6400 Sheets/h | 5600 Sheets/h | |||

| Accuracy | ± 1,0 | ± 1,0 | ± 1,5 | ± 1,5 | ± 1,5 | ± 1,5 | |||

| Machine Dimension (L/W/H) | 13226 × 2860 × 2180 | 13226 × 3100 × 2180 | 10050 × 2394 × 2180 | 12515 × 2544 × 2180 | 12515 × 2740 × 2180 | 12515 × 2940 × 2180 | |||

| REMARK: | Automatic setup | ||||||||

| ALSO AVAILABLE: | Auto Cardboard Laminating machine | ||||||||

| OPTIONS: | • Lead Edge Bottom feeder, • Electronic Roller gap adjustement, • Memory function | ||||||||

FILM LAMINATING MACHINE

| SPECIFICATIONS | 108E | 145E | 145D | 165D | ||||

|---|---|---|---|---|---|---|---|---|

| Maximum Laminating Width | 1080 mm | 1080 mm | 1300 mm | 1300 mm | FEATURES: | |||

| Maximum Sheet Size (mm) | 1080 × 1080 mm | 1080 × 1450 mm | 1300 × 1450 mm | 1300 × 1650 mm | 1. High speed feeder and servo control device which ensures more accurate | |||

| Minimum Sheet Size (mm) | 350 × 350 mm | 350 × 350 mm | 350 × 350 mm | 350 × 350 mm | and steady stacking of the paper | |||

| Paper Thickness | 100 - 500 | 100 - 500 | 100 - 500 | 100 - 500 | 2. The whole machine adopts thermal energy cycling system, high speed and | |||

| Film Thickness (mm) | 6 - 25 | 6 - 25 | 6 - 25 | 6 - 25 | environment protection | |||

| Machine Speed (m/min) | 10 - 80 | 10 - 80 | 10 - 80 | 10 - 80 | 3. Cold water non-curling system: The paper will be non-curling after separation | |||

| Laminating Speed (m/min) | 10 - 70 | 10 - 70 | 10 - 70 | 10 - 70 | 4. Chain knife/Hot knife (optional) with disc knife is suitable for multi-lateral | |||

| Machine Dimension (L/W/H) | 10765 × 2754 × 2926 mm | 10765 × 2754 × 2926 mm | 12618 × 2754 × 2926 mm | 13018 × 2754 × 2926 mm | lamination | |||

| Machine Weight | 8,6 Tons | 9,5 Tons | 10,9 Tons | 11,5 Tons | 5. Anti-static powder removing system ensures process production quicker | |||

| Total Power | 63 - 68 kW | 63 - 68 kW | 63 - 68 kW | 63 - 68 kW | 6. Non-stop feeder and delivery device for production with high efficiency | |||

| REMARK: | Chain or Steinemann Hot knife available. | |||||||

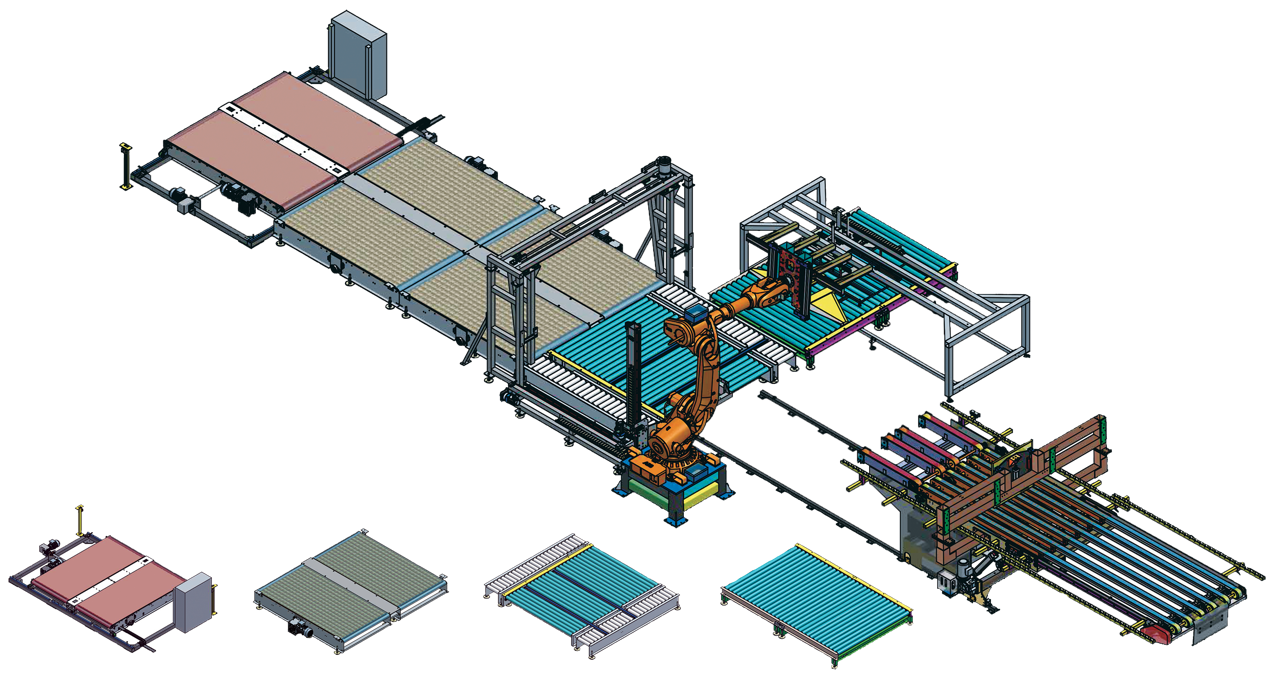

LOGISTIC EQUIPMENT

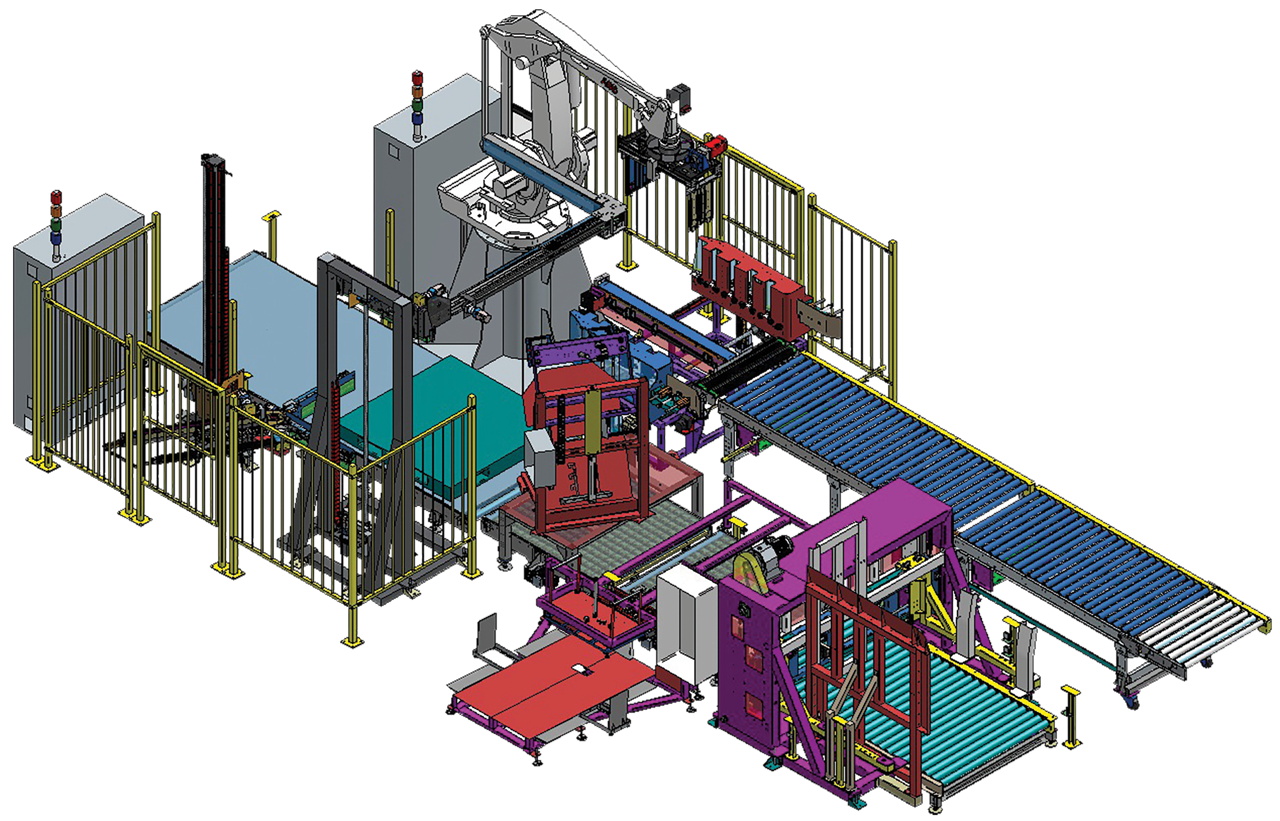

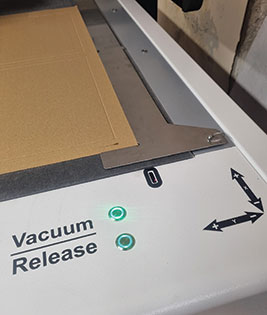

ROBOT PREFEEDER

| SPECIFICATIONS | Robot Pre-Feeder | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cardboard Dimension | Max. 2900 × 1600 / Min. 750 × 340 mm | ||||||||

| Stacking Height | 1800 mm | ||||||||

| Maximum Weight of Gripping | 60 kg | ||||||||

| Maximum Height of Gripping | 400 mm | ||||||||

| Cycle Time | Approx. 10 Times/ Minute | ||||||||

| Printing Position | Top Print / Bottom Print | ||||||||

| Maximum Stack Height (with Pallet) | 1800 mm | ||||||||

| Maximum Stack Weight (with Pallet) | 1,8 Tons | ||||||||

| Gripping Height | Max. 400 / Min. 50 mm | ||||||||

| Average Gripping Speed | Approx. 300 ~ 400 Sheets/ Min | ||||||||

| REMARK: | The full inline system consists of folowing eqipment: Robot Prefeeder, Robot Gripper, Robot Arm unit, Bottom board vaccuming unit, Roller conveyer, Bottom board separating part, Traverse Roller Conveyer, Stopper part, Plastic modular belt Buffer conveyer, Centraing plastic modular belt conveyer | ||||||||

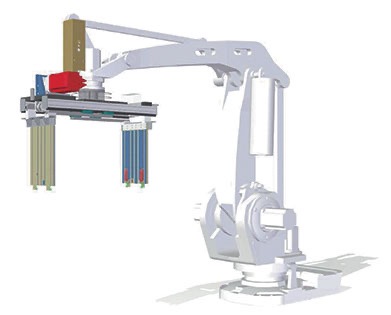

ROBOT PALLETIZER

| SPECIFICATIONS | Robot Palletizing System | Square Aligner For Stacking | FRDC Palletizing System | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| *Type HL-1412H (Suitable For Printing Machine #1228) | Maximum Stack Height | 1800 × 1800 × 1800 mm | Bundle Size | Max. 1650 × 1200 / Min. 400 × 400 mm | |||||||||||

| Sheet Size | Max. 1250 × 1450 / Min. 290 × 330 mm | Minimum Stack Size | 700 × 900 × 200 mm | Slipsheet | 1200 × 1200 mm | ||||||||||

| Pallet Size | Max. 1500 × 1500 / Min. 1200 × 1000 mm | REMARK: | Full Line Consist of: | Bottom Sheet | 1800 × 1600 mm | ||||||||||

| *Type HL-1210H (Suitable For Printing Machine #924) | *Standard Positioner Type | Stacking Area | 1650 × 1650 mm | ||||||||||||

| Sheet Size | Max. 1050 × 1250 / Min. 250 × 330 mm | *Plastic Chains Pallet Output Conveyor | Stacking Height (without Pallet) | 2,000 mm | |||||||||||

| Pallet Size | Max. 1500 × 1500 / Min. 1000 × 1200 mm | *Multi-Type Pallet Palletizer | Maximum Weight | 100 kgs per Layer | |||||||||||

| *Type HL-960H (Suitable For Printing Machine #618) | *Side Pusher | Other Than Standard | Customization Available Upon Request. | ||||||||||||

| Sheet Size | Max. 600 x 900 / Min. 200 x 220 mm | Other Than Standard | Customization Available Upon Request. | ||||||||||||

| Pallet Size | Max. 1500 x 1500 / Min. 1000 x 1200 mm | REMARK: | The full inline system consists of folowing eqipment: IPC Control unit, | ||||||||||||

| *Common data | Plastic modular belt conveyor for shipment, Chain Conveyor for buffer, Roller Supply | ||||||||||||||

| Max. Gripping Payload | 35 kgs | Maximum Stack Height | 1800 mm | conveyor, Roller shipping conveyor, Plastic modular belt conveyor for working | |||||||||||

| Gripping Height | Max. 400 mm/ Min. 50 mm | Maximum Stack Weight | 1800 kgs | area, Feed roller conveyor, Oscillating feed roller conveyor, Liftable and swingable | |||||||||||

| Stacking Speed | Approx. 18 Cycles per Min. | Paper-Layer Size | Max. 1300 × 1300 mm / Min. 900 × 500 mm | roller conveyor, Robotic arm unit, Robot gripper, Positioner, Bottom plate feeder, | |||||||||||

| Maximum Stack Size | Pallet Size + 0.3 M | Other Than Standard | Customization Available Upon Request. | Single pallet feeder, Multi pallet feeder, Slip sheet feeder, Workspace palletizing | |||||||||||

SPECIALISED EQUIPMENT

PULP MOULD FORMING MACHINE

| ROTARY | 2880 | 3600 | 4300 | 5000 | 6000 | 7200 | RECIPROCATION | 1200 | 1350 | 1400 |

|---|---|---|---|---|---|---|---|---|---|---|

| Template Size | 1500 × 440 mm | 1950 × 440 mm | 2250 × 440 mm | 1500 × 440 mm | 1950 × 440 mm | 2250 × 440 mm | Template Size | 1200 × 660 mm | 1350 × 900 mm | 1400 × 1200 mm |

| Egg Tray Capacity/hr | 2880 pcs | 3600 pcs | 4300 pcs | 5000 pcs | 6000 pcs | 7200 pcs | Capacity/hr | 200 kg | 265 kg | 300 kg |

| Maximum Running Speed (times/min) | 12 | 12 | 12 | 20.8 | 20 | 20 | Maximum Product Size | 1150 × 610 mm | 1300 × 850 mm | 1350 × 1150 mm |

| Product Thickness | 1-1.5 mm | 1-1.5 mm | 1-1.5 mm | 1-1.5 mm | 1-1.5 mm | 1-1.5 mm | Minimum Product Size | 100 × 100 mm | 100 × 100 mm | 100 × 100 mm |

| {6-Layer Drying Line Length} | 11 m | 11 m | 11 m | 17 m | 17 m | 17 m | Maximum Running Speed (times/min) | 1-3 | 1-3 | 1-3 |

| Suggested Workshop Size | 40 × 15m | 40 × 15m | 40 × 15m | 50 × 15m | 50 × 20m | 50 × 20m | Product Thickness | 1.5-4 mm | 1.5-4 mm | 1.5-4 mm |

| Nature Gas Consumption | 50m³/h | 60m³/h | 72m³/h | 83m³/h | 100m³/h | 120m³/h | 1-Layer Drying Line Length | 24 m | 30 m | 40 m |

| Total Power | 110kW | 120kW | 140kW | 160kW | 200kW | 240kW | Suggested Workshop Size | 40 × 15 m | 45 × 15 m | 50 × 15 m |

| OPTIONS: | Thermoforming machine also available. | Total Power | 160kW | 200kW | 220kW | |||||

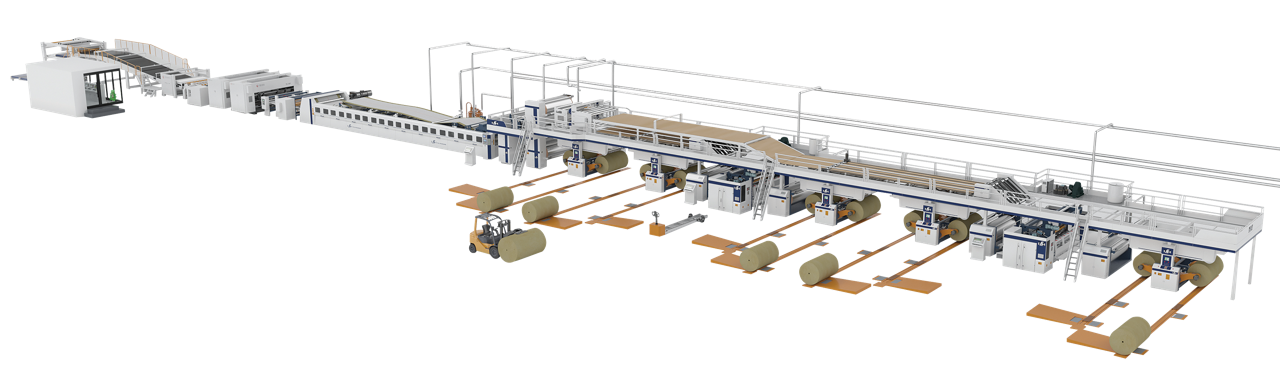

CORRUGATOR

IN CHINA

.jpg)

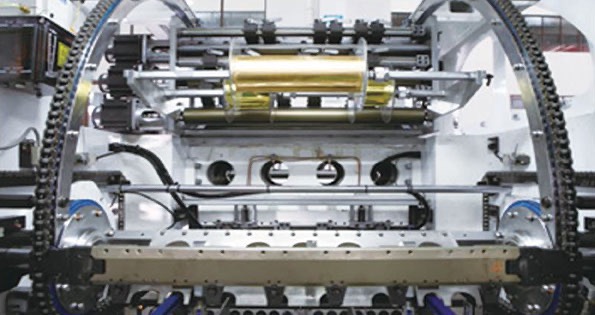

AUTO SERVO SPLICER (DOUBLE CLOSED-LOOP)

CASSETTE TYPE SINGLE FACER

HEAVY DUTY DRIVE

MULTI LAYER PRE-HEATER/PRECONDITIONER

GLUE APPLYING MACHINE

.jpg)

HYDRAULIC MILL ROLL STAND (SHAFTLESS)

| SPECIFICATIONS | High Speed Corrugated Cardboard Production Line |

|---|---|

| Web Size | 1800 – 3100 mm |

| Designed Speed | 200 – 450 m/min |

| A single source solution for 2/3/4/5/7/9 ply cardboard production | Heating area adjustable by motorized paper guide roll adjustment |

| Flute Type | A/C/B/E/F/G and others |

| Way Of Heating | Steam Heating |

| • Complete set of 3/5/7/9 Ply High Speed Corrugated Cardboard production line includes the following machines: | |

|

Hydraulic Mill Roll Stand, Pre-Heater, Pre-conditioner, Splicer, Single Facer, Over Bridge, Bridge Traction, Multi-layer Pre-Heater, Glue Machine, Double Baker, Main Drive, N.C. Slitter Scorer, N.C. Cut-off, Stacker and Ect. |

|

PLOTTER

| SPECIFICATIONS | CMS 1013 | CMS 1613 | CMS 2113 | CMS 2517 | CMS 3217 | CMS 2520 | CMS 3220 |

|---|---|---|---|---|---|---|---|

| Working area (mm) | 1000 × 1300 | 1600 × 1300 | 2100 × 1300 | 2517 × 1700 | 3217 × 1700 | 2520 × 2000 | 3220 × 2000 |

| • Tool length measuring system with lasersensor | • Main axes (X-axis; Y-axis) equipped with linear measuring systems | ||||||

| • Energy-efficient, controllable vacuum turbinese with separate zones | • Laser pointer for exact positioning of the tools | ||||||

| • 1 kW milling unit with automatic tool changer with cleaning unit for up to 10 tools | • Bumper system with light barriers for security | ||||||

| • Camera system - modular optical recognition software system | • Extensive service and utility programs | ||||||

| • Predefined material database that can be edited by the operator | • Remote maintenance possible | ||||||

| • Automatic scanning, storage and correction of table surface irregularities | • Alternating operation for small runs | ||||||

| OPTIONS: Double side production for small runs | |||||||

LASER

| SPECIFICATIONS | MTL 1521 | MTL 1525 |

|---|---|---|

| Working area | 1500 × 2100 mm | 1500 × 2500 mm |

| • Coherent Slyb 3 Lasersource | ||

| • 3D Crash Protect | ||

| • Height adjustable Industry PC with graphic Touch screen panel | ||

| • LaserScan - Engraving System for the rational engraving of information on dieboards | ||

| • Pneumatic clambing system | ||

| • Loading support | ||

| • Steel cutting | ||

| OPTIONS: Rotary Laser also available | ||

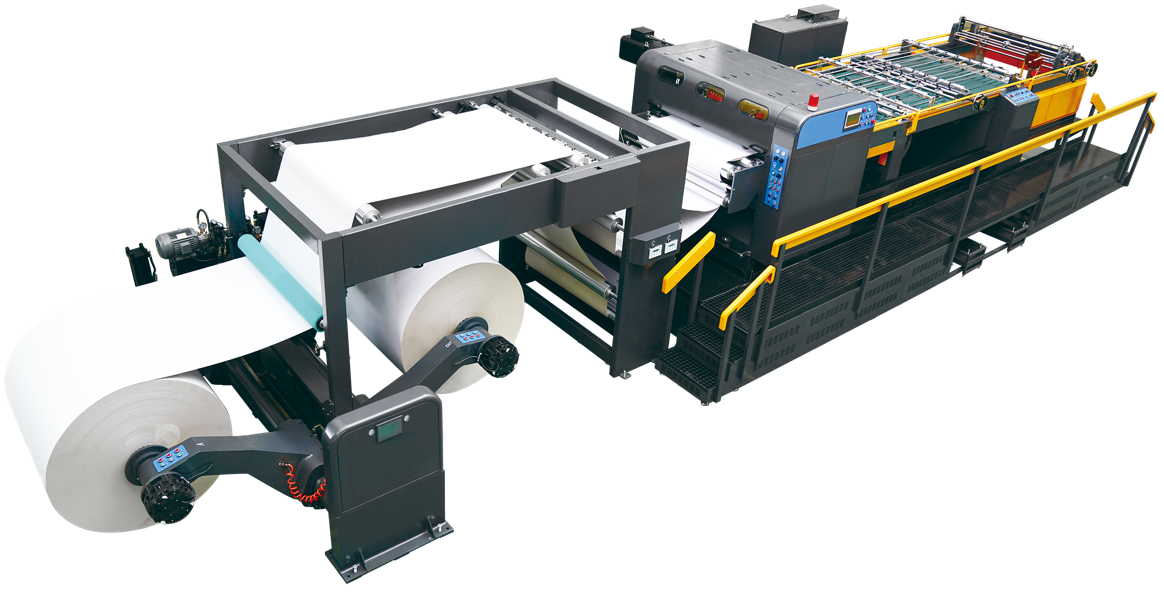

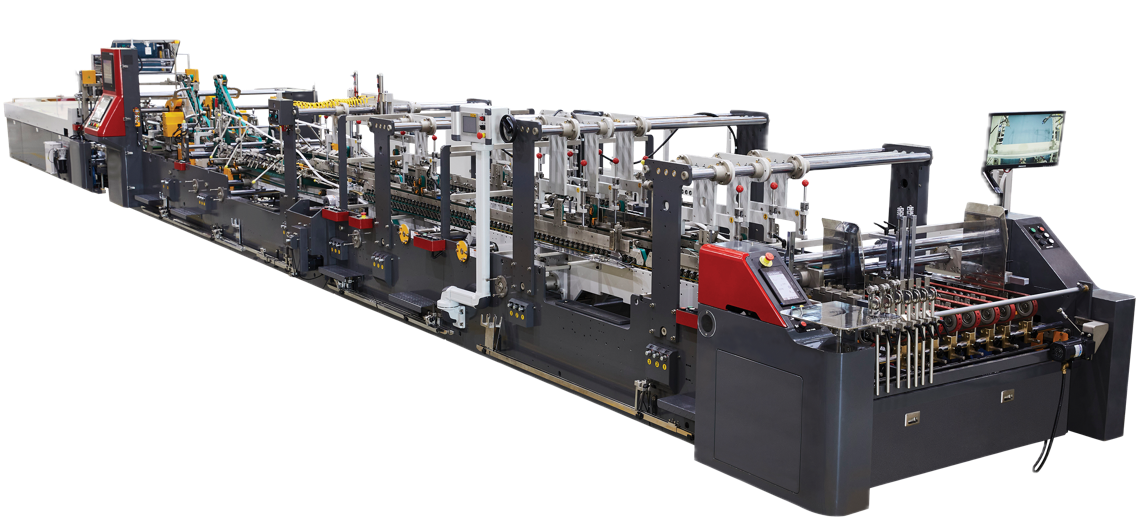

SHEET CUTTER

| SPECIFICATIONS | 1400 | 1700 | 1900 |

|---|---|---|---|

| Type of Cutting | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed | Top blade rotary, bottom blade fixed |

| Weight of Paper | 60 - 550 GSM | 60 - 550 GSM | 60 - 550 GSM |

| Reel Diameter | Maximum 1800 mm | Maximum 1800 mm | Maximum 1800 mm |

| Finished Width | Maximum 1400 mm | Maximum 1700 mm | Maximum 1900 mm |

| Finished Sheet-Length | Minimum 450, Maximum 1800 mm | Minimum 450, Maximum 1450 mm | Minimum 450, Maximum 1650 mm |

| Number of Rolls Cutting | 2 rolls | 2 rolls | 2 rolls |

| Cutting Accuracy | ± 0.5 mm (L < 1000 mm) | ± 0.5 mm (L < 1000 mm) | ± 0.5 mm (L < 1000 mm) |

| ± 0.1 % (L ≥ 1000 mm) | ± 0.1 % (L ≥ 1000 mm) | ± 0.1 % (L ≥ 1000 mm) | |

| Maximum Speed of Cutting | 300 cuts/min | 300 cuts/min | 300 cuts/min |

| Maximum Cutting Speed | 300 m/min | 300 m/min | 300 m/min |

| Requirement of the Air Pressure | 0.8MPa | 0.8MPa | 0.8MPa |

| Voltage | AC 380V /220V × 50Hz | AC 380V /220V × 50Hz | AC 380V /220V × 50Hz |

| Total Power | 29 kW | 30 kW | 41 kW |

OUR TEAM

CEO

Executive Manager

Sales Manager

Sales Manager, Slovenia, CROATIA, F.Bih

Sales Manager, Austria, Germany and Hungary

HEAD OF TECHNICAL DEPARTMENT

CZECH REPUBLIC, SLOVAKIA and POLAND

POLAND

POLAND

SERBIA, MONTENEGRO, MACEDONIA, KOSOVO, REP. SRPSKA

ROMANIA

BULGARIA

Service network

PAMA Paper Machinery

is offering you a wide range of services, which includes installation, training of your staff, local service, maintenance and technical support for all our products.

All spare parts are delivered to you in shortest possible time and we are strongly focused on fast supply of all needed spare parts.

We have 6 specialized service teams for efficent and quick technical support located in Poland, Czech Republic, Serbia, Romania, Hungary and Slovenia.

CONTACT

Barletova cesta 4z

1215 Medvode, Slovenia

| Tel: | +386 1 3623 156 |

| Mob: | +386 41 779 020 / Matjaž Jamnik |

| +386 40 193 997 / Edi Halilovič | |

| +386 31 639 449 / Laura Žolnir | |

| E-mail: | pama@pa-ma.com |

| Web: | www.pa-ma.com |